Building structures continuously move from thermal expansion and contraction, seismic forces, wind loading, settlement, and creep – movements that generate internal stresses capable of cracking concrete, buckling cladding, and failing building envelope systems. Expansion joints strategically placed throughout structures accommodate these movements, preventing damage by creating intentional separations that allow adjacent building elements to move independently.

Understanding expansion joint design principles, calculating expected movements, and implementing proper sealing systems ensures buildings handle dynamic forces gracefully throughout their service life. Whether you’re designing large commercial complexes, specifying facade systems, or maintaining existing facilities, proper expansion joint treatment proves essential to structural integrity and building longevity.

Understanding Building Movement and Expansion Joints

All building materials expand when heated and contract when cooled – a physical reality that generates substantial forces and movements in structures. Without proper accommodation, these thermally-induced movements crack rigid materials, buckle restrained elements, and fail envelope systems.

Why Expansion Joints Are Necessary

Thermal expansion creates forces far exceeding structural capacity if restrained. Consider a 50-meter concrete wall exposed to 40°C temperature change – without expansion joints, thermal expansion generates compressive stress exceeding 3,000 kPa, easily crushing masonry and cracking concrete. Expansion joints eliminate this stress by allowing free movement.

Different materials expand at different rates creating additional challenges. A metal panel expanding twice as much as adjacent concrete creates differential movement that tears connections or buckles panels. Properly designed joints accommodate these material differences preventing damage.

Multi-story buildings experience complex movement patterns. Upper floors deflect more than lower floors under wind loading, seismic events create relative displacement between stories, and long-term settlement occurs unevenly. Expansion joints address these diverse movement sources systematically.

Sources of Building Movement

Understanding movement sources guides expansion joint design and placement.

Thermal expansion and contraction represents the primary movement source in most buildings. Materials expand when temperature rises and contract when temperature falls – the magnitude depending on material coefficient of thermal expansion (CTE) and temperature range.

Common material thermal expansion coefficients:

- Concrete: 10-14 × 10⁻⁶ per °C

- Steel: 12 × 10⁻⁶ per °C

- Aluminum: 23 × 10⁻⁶ per °C (nearly double concrete/steel)

- Glass: 8-9 × 10⁻⁶ per °C

- Natural stone: 5-12 × 10⁻⁶ per °C (varies by type)

- Plastics/composites: 30-150 × 10⁻⁶ per °C

These differences explain why joints between dissimilar materials require special attention – aluminum cladding expands twice as much as concrete structure beneath it.

Seismic movement from earthquakes creates rapid, substantial displacements. Modern seismic building codes require story drift capacity typically 1-2% of story height – for a 4-meter story height, that’s 40-80mm potential movement. Expansion joints must accommodate this without failing.

Wind loading flexes buildings creating inter-story displacement. Tall buildings sway under wind loads, with upper floors displacing more than lower floors. Cladding systems must accommodate this differential movement without damage.

Settlement and creep cause long-term movements. Differential settlement from varying soil conditions, foundation types, or loading patterns creates angular distortion requiring joint accommodation. Concrete creep – time-dependent deformation under sustained load – also contributes gradual movement.

Moisture-related movement affects some materials. Concrete and masonry experience drying shrinkage after construction, while some materials expand with moisture absorption. These dimensional changes combine with thermal movements requiring consideration in joint design.

Expansion Joint Types and Applications

Expansion joints fall into categories by location and function.

Building expansion joints separate entire building sections allowing independent movement. These full-height separations from foundation to roof typically occur every 30-60 meters in long buildings, at L-shaped or T-shaped plan junctions, and between dissimilar structural systems.

Facade and cladding joints accommodate movement in exterior envelope systems. These joints allow differential movement between cladding and structure while maintaining weatherproofing. Curtain wall systems, metal panels, and stone cladding all require carefully designed movement joints.

Floor and pavement joints handle movement in horizontal surfaces. Concrete floor slabs, plaza decks, and paving require control joints managing shrinkage and thermal movement. Industrial floors face additional challenges from heavy equipment loading.

Roof expansion joints accommodate large thermal movements in roof systems. Dark roofing membranes can reach 70-80°C in direct sun creating substantial expansion compared to cool nighttime temperatures. These extreme temperature ranges demand robust joint systems.

Calculating Expected Movement

Accurate movement prediction determines proper joint sizing and sealant selection. Underestimating movement leads to joint failure, while excessive conservatism wastes resources.

Thermal Movement Calculation

Thermal movement calculation follows straightforward formula:

ΔL = α × L × ΔT

Where:

- ΔL = change in length (mm)

- α = coefficient of thermal expansion (per °C)

- L = length of element (mm)

- ΔT = temperature change (°C)

Example: Concrete exterior wall

- Material: Concrete, α = 12 × 10⁻⁶ per °C

- Length: L = 30,000 mm (30 meters)

- Temperature range: ΔT = 50°C (from 5°C to 55°C)

ΔL = 12 × 10⁻⁶ × 30,000 × 50 = 18 mm

This 30-meter wall expands/contracts 18mm total – requiring joints accommodating ±9mm movement if centered.

Middle Eastern example: Aluminum curtain wall

- Material: Aluminum, α = 23 × 10⁻⁶ per °C

- Length: L = 20,000 mm (20 meters between expansion joints)

- Temperature range: ΔT = 60°C (from 15°C to 75°C – aluminum panels in direct sun)

ΔL = 23 × 10⁻⁶ × 20,000 × 60 = 27.6 mm

This demonstrates why desert climates with extreme temperature ranges create such demanding conditions – movement nearly 50% larger than temperate climate example.

Temperature Range Determination

Accurately determining temperature range proves critical to movement calculation.

Service temperature range differs from air temperature. Material surface temperatures in direct sun can exceed air temperature by 20-40°C or more. Dark surfaces reach even higher temperatures.

Typical material temperature ranges by climate:

Desert/Middle East (example: Dubai, Riyadh):

- Concrete/masonry: 5°C to 60°C (ΔT = 55°C)

- Metal panels (dark): 10°C to 75°C (ΔT = 65°C)

- Roofing membrane (black): 15°C to 85°C (ΔT = 70°C)

- Glass curtain wall: 10°C to 65°C (ΔT = 55°C)

Temperate climate (example: Northern Europe, Northern US):

- Concrete/masonry: -10°C to 40°C (ΔT = 50°C)

- Metal panels: -15°C to 50°C (ΔT = 65°C)

- Roofing membrane: -10°C to 70°C (ΔT = 80°C)

Tropical humid (example: Southeast Asia):

- Concrete/masonry: 20°C to 50°C (ΔT = 30°C)

- Metal panels: 20°C to 60°C (ΔT = 40°C)

Note that roofing membranes experience largest temperature ranges regardless of climate due to solar heating.

Combined Movement Calculations

Real-world joints experience multiple movement sources simultaneously.

Total movement = Thermal movement + Seismic displacement + Settlement + Construction tolerances

For critical joints, add 25-50% safety factor accounting for uncertainties and aging effects reducing sealant capability.

Example: Facade expansion joint calculation

Thermal movement: 20mm (calculated above) Seismic displacement: 15mm (1.5% story drift × 1,000mm between joints) Construction tolerance: ±3mm Safety factor: 30%

Total design movement = (20 + 15 + 3) × 1.3 = 49mm

This joint must accommodate ±25mm movement (half total) requiring high-performance sealant rated ±50% movement in properly sized joint.

Expansion Joint Design Principles

Proper expansion joint design balances movement accommodation with structural requirements, weatherproofing needs, and constructability.

Joint Width Sizing

Joint width must accommodate expected movement while maintaining proper sealant geometry.

Design joint width = Expected total movement ÷ Sealant movement capability

For sealant rated ±25% movement:

- Total movement = 20mm

- Required width = 20 ÷ 0.25 = 80mm minimum

- Design width = 80 + 25% = 100mm (adding safety margin)

For sealant rated ±50% movement:

- Same 20mm total movement

- Required width = 20 ÷ 0.50 = 40mm minimum

- Design width = 40 + 25% = 50mm

This demonstrates how higher-capability sealants allow narrower joints – important where wide joints create architectural or practical problems.

Practical joint width ranges:

- Minimum practical width: 12-15mm (smaller joints difficult to seal properly)

- Typical building expansion joints: 25-50mm

- Seismic joints: 50-150mm depending on expected displacement

- Bridge/infrastructure joints: 50-300mm

Joint Depth and Geometry

Proper joint depth ensures optimal sealant performance.

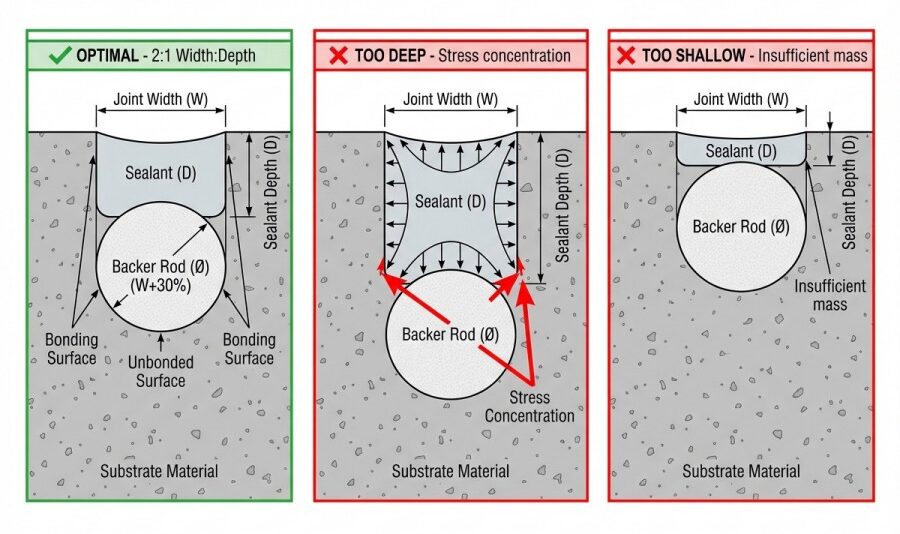

Width-to-depth ratio critically affects sealant behavior. Optimal ratio typically 2:1 (width:depth) allows sealant to stretch and compress properly without excessive stress concentration.

Sealant depth guidelines:

- Joints 6-12mm wide: depth = width (1:1 ratio)

- Joints 12-25mm wide: depth = width or width/2 (1:1 to 2:1)

- Joints >25mm wide: depth = width/2 (2:1 ratio), maximum 12-15mm depth

Excessive depth (too narrow ratio) creates high stress concentration as sealant deforms. Too shallow (too wide ratio) provides inadequate mass for movement accommodation.

Backer rod selection controls sealant depth. Use closed-cell polyethylene backer rod sized 25-30% larger than joint width for proper compression fit. Backer rod prevents three-sided adhesion – sealant bonding to joint bottom restricts movement causing premature failure.

Joint Spacing Guidelines

Joint spacing depends on material type, temperature range, and structural system.

Concrete structures:

- Standard practice: 30-60 meter spacing

- High temperature range: 20-40 meter spacing

- Reinforcement level: heavily reinforced structures tolerate longer spacing

Masonry walls:

- Typical spacing: 20-40 meters

- Varies by: mortar type, reinforcement, support conditions

Metal cladding:

- Panel-to-panel joints: every panel (600-1500mm typically)

- Expansion joints: 15-30 meters

Stone cladding:

- Panel-to-panel joints: every panel

- Expansion joints: 10-20 meters (stone’s low thermal expansion allows longer spacing)

Floor slabs:

- Control joint spacing: 24-30 times slab thickness (in feet)

- Isolation joints: at columns, walls, penetrations

- Construction joints: at pour boundaries

Sealant Selection for Expansion Joints

Expansion joint sealants must accommodate substantial movement while maintaining weatherproofing and durability. Movement capability, durability, and adhesion determine suitability.

Movement Capability Requirements

Sealant movement capability expressed as ±percentage of joint width determines ability to handle expansion and contraction.

Movement capability classes:

±25% movement – Standard capability adequate for moderate applications:

- Protected interior joints

- Small temperature ranges

- Supplementary joints with primary structural system

±50% movement – High performance suitable for most exterior applications:

- Exterior facade joints in temperate climates

- Typical expansion joints in most structures

- Products like BoPin 770 Weatherproof Neutral Silicone rated ±50% movement

±100% movement – Maximum performance for extreme demands:

- Desert climate applications with extreme temperature ranges

- Seismic joints requiring large displacement capacity

- Joints with combined thermal and structural movement

- Specialty applications requiring maximum flexibility

Calculating required movement capability:

Joint width: 40mm Expected total movement: 30mm Required capability: 30 ÷ 40 = 75% (requires ±100% rated product with safety margin)

Recommended Sealant Types

Different sealant chemistries offer varying movement capabilities and characteristics.

Silicone sealants provide excellent movement capability, weather resistance, and durability. Neutral-cure silicones like BoPin 770 Weatherproof Silicone handle demanding exterior applications through:

- ±50% movement capability standard (some products ±100%)

- Temperature resistance -40°C to +150°C

- Superior UV and weather resistance

- Decades of service life in exposed conditions

- Excellent adhesion to diverse substrates

MS polymer sealants offer good performance with paintability. Products like BoPin MS-220 Multi-Purpose MS Polymer suit applications where:

- ±50% movement capability sufficient

- Paintability required for aesthetic reasons

- Excellent adhesion needed

- Temperature range -40°C to +90°C adequate

Polyurethane sealants provide good performance at moderate cost:

- ±25% to ±50% movement capability (product dependent)

- Good adhesion and abrasion resistance

- Temperature range typically -25°C to +80°C

- UV sensitivity limits exposed roof applications

Polysulfide sealants offer maximum movement capability:

- ±100% movement capability

- Excellent chemical resistance

- Good long-term flexibility

- Poor UV resistance (interior or buried applications only)

- Slow cure and strong odor during application

Climate-Specific Considerations

Climate dramatically affects sealant selection and performance expectations.

Desert/Middle East applications:

Extreme temperature ranges (60-70°C) and intense UV demand:

- Maximum UV resistance – premium silicones or specialized products

- High movement capability – ±50% minimum, ±100% preferred for large joints

- Heat resistance – maintain properties at 70-80°C surface temperatures

- Thermal stability – withstand daily cycling without fatigue

- Low dirt pickup – clean appearance in dusty environments

Products like BoPin 770 Weatherproof Silicone specifically formulated for demanding conditions handle these requirements effectively.

Tropical/coastal applications:

High humidity and biological growth risk require:

- Moisture resistance – maintain adhesion in constant humidity

- Anti-fungal properties – prevent mold/algae growth

- Salt resistance – withstand salt spray in coastal locations

- Rapid cure – moisture-cure products cure quickly in high humidity

Cold climate applications:

Freeze-thaw cycling and low temperatures demand:

- Low-temperature flexibility – maintain flexibility to -40°C

- Freeze-thaw resistance – withstand hundreds of freeze-thaw cycles

- Cold application capability – some products apply to 0°C or -5°C

- Ice adhesion resistance – prevent ice bonding damaging sealant

Expansion Joints in Different Building Systems

Expansion joint requirements vary by building system and location. Understanding system-specific needs ensures appropriate solutions.

Facade and Curtain Wall Expansion Joints

Exterior envelope systems require joints accommodating thermal movement while maintaining weatherproofing.

Curtain wall expansion joints typically occur every 15-25 meters depending on panel material and climate. These joints must accommodate:

- Thermal expansion of aluminum framing (23 × 10⁻⁶ per °C)

- Building structure movement

- Inter-story drift from wind/seismic loads

- Installation tolerances

Joint design considerations:

- Primary weatherproofing from joint system (gaskets, covers)

- Secondary seal from sealant backup

- Drainage provisions for any water penetrating primary seal

- Visibility – architectural appearance requirements

Nguyên vật liệu: High-performance silicones provide optimal combination of movement capability, weather resistance, and longevity for exposed facade applications.

Concrete Floor and Slab Expansion Joints

Floor slabs require control joints managing shrinkage and thermal movement while maintaining flatness and load transfer.

Control joint spacing typically 24-30 times slab thickness (in feet). A 150mm (6-inch) slab requires joints every 36-45 meters maximum.

Joint types:

- Control joints – shallow sawcuts inducing cracking at planned locations

- Construction joints – between pours, may include dowels for load transfer

- Isolation joints – full-depth separations at columns, walls, equipment

Sealant requirements:

- Trafficability – resist abrasion from foot and equipment traffic

- Flush surface – self-leveling products create smooth transitions

- Khả năng kháng hóa chất – handle cleaning chemicals and spills

- Load transfer – some joints use specialized systems maintaining structural connection

For industrial applications: Refer to comprehensive guidance in our Industrial Floor and Warehouse Joint Sealing Guide.

Roof Expansion Joints

Roof systems experience extreme temperature ranges requiring robust expansion joint systems.

Nhiệt độ cực đoan on roofs exceed those elsewhere. Black membrane roofs can reach 85°C in peak sun then cool to 15°C overnight – 70°C daily temperature swing creates substantial movement.

Roof expansion joint systems typically use:

- Raised curbs elevating joints above roof surface

- Metal covers protecting sealant from direct exposure

- Flexible bellows or compression systems accommodating movement

- Backup sealant providing secondary weatherproofing

For metal roof applications: See detailed guidance in our Metal Roof and Panel Sealing Guide.

Plaza Deck and Parking Structure Joints

Traffic-bearing surfaces face additional challenges from vehicle loading and waterproofing requirements.

Trafficked expansion joints must:

- Support wheel loads without damage

- Remain waterproof preventing infiltration to structure below

- Accommodate movement under traffic and temperature changes

- Provide smooth transitions preventing tripping hazards or vehicle impacts

Specialized joint systems for these applications include:

- Armored joints with metal edge protection

- Modular systems with replaceable components

- Drainage provisions directing water away from joint

- Flexible yet durable materials surviving traffic abuse

Các phương pháp lắp đặt tốt nhất

Proper installation techniques ensure expansion joints perform as designed. Even premium products fail if installed incorrectly.

Chuẩn bị bề mặt

Thorough surface preparation proves critical to sealant adhesion and long-term performance.

Concrete substrates:

- Remove laitance from sawcut or formed surfaces

- Làm sạch kỹ lưỡng removing dust, dirt, curing compounds

- Verify dryness – concrete moisture typically <4% for most sealants

- Prime if required per manufacturer specifications

Metal substrates:

- Clean with solvents removing oils, greases, protective coatings

- Abrade glossy surfaces improving mechanical adhesion

- Prime as specified – many metals require primers for reliable bonding

- Kiểm tra khả năng tương thích – some metals (copper, lead) may require special products

Cleaning products like BoPin CL-900 Professional Cleaning Solution effectively clean substrates without leaving residue.

Backer Rod Installation

Proper backer rod installation controls sealant depth and prevents bond breaker failure.

Backer rod selection:

- Closed-cell polyethylene for most applications

- Size 25-30% larger than joint width for compression fit

- Appropriate firmness – too soft compresses excessively, too firm difficult to install

Installation technique:

- Install at proper depth achieving 2:1 width:depth ratio

- Avoid stretching – stretched backer rod may recoil distorting joint

- Use insertion tools for narrow or deep joints

- Verify position before sealant application

Sealant Application

Proper application technique affects both performance and appearance.

Application conditions:

- Temperature range per product specifications (typically +5°C to +35°C)

- Dry substrates – no surface moisture

- Protected from precipitation during cure period (24-48 hours minimum)

- Proper ventilation for solvent-based products

Kỹ thuật ứng dụng:

- Continuous beads without gaps or voids

- Complete joint filling from backer rod to surface

- Proper gunning speed creating consistent bead size

- Immediate tooling while sealant workable

Tooling:

- Appropriate tools matching joint size and geometry

- Concave profile optimal for most joints

- Smooth finish ensuring complete substrate contact

- Gỡ băng keo che chắn shortly after tooling while sealant still soft

Quality Control and Testing

Verification procedures ensure installations meet specifications.

Visual inspection:

- Continuous beads without gaps

- Proper profile achieved through tooling

- Good adhesion – no gaps at edges

- Consistent appearance throughout project

Adhesion testing:

- Pull test sample joints verifying adhesion

- Wait appropriate cure time before destructive testing

- Evaluate failure mode – cohesive (good), adhesive (problem)

Movement testing:

- Mock-up panels demonstrating performance

- Cycle test – opening and closing joint verifying sealant recovery

- Long-term observation of test panels

Common Failure Modes and Prevention

Understanding typical expansion joint failures guides prevention strategies.

Undersized Joints

Joints too narrow for expected movement represent the most common design error.

Symptoms:

- Cohesive failure – sealant tears internally

- Adhesive failure at maximum extension

- Substrate damage from excessive stress

Prevention:

- Accurate movement calculation including all sources

- Adequate safety factors (25-50% typical)

- Select appropriate movement capability sealants

Correction:

- Widen existing joints if possible

- Install higher movement capability sealants

- Add intermediate joints reducing individual joint movement

Three-Sided Adhesion

Sealant bonding to joint bottom prevents proper movement creating premature failure.

Causes:

- Missing or inadequate backer rod

- Backer rod installed too deep

- Joint too shallow for proper backer rod placement

Prevention:

- Always use proper backer rod

- Install at correct depth achieving 2:1 width:depth ratio

- Verify backer rod position before sealant application

Symptoms:

- Sealant tears at substrate interface rather than stretching

- Early failure despite adequate joint width

Inadequate Surface Preparation

Poor adhesion from contaminated substrates causes widespread failures.

Common contaminants:

- Form release agents on concrete

- Oils and greases on metals

- Dirt and dust on any substrate

- Previous sealant residue not completely removed

Prevention:

- Thorough cleaning with appropriate methods

- Verify cleanliness before sealant application

- Use specified primers when required

- Allow proper drying time after cleaning

Excessive Movement or Unforeseen Loading

Actual movement exceeding design assumptions overloads joints causing failure.

Causes:

- Inaccurate movement calculations

- Unanticipated load conditions (seismic events, settlement)

- Material changes altering thermal properties

- Sealant aging reducing movement capability

Response:

- Document failure conditions understanding causes

- Revise calculations based on actual performance

- Upgrade to higher performance products

- Modify joint geometry if needed

Inspection and Maintenance

Regular inspection identifies developing problems before catastrophic failure, while proactive maintenance extends joint service life.

Inspection Procedures

Systematic inspection schedules depend on exposure and criticality.

Inspection frequency:

- Exterior exposed joints: Annual minimum, preferably semi-annual

- Protected interior joints: Every 2-3 years

- Critical structural joints: Annual with detailed documentation

- High-movement joints: More frequent based on performance

Inspection checklist:

- Sealant adhesion – probe gently checking bond integrity

- Cohesion – look for cracks, tears, splits

- Joint width – measure verifying adequate width maintained

- Substrate condition – check for spalling, cracking, corrosion

- Movement evidence – sealant deformation indicating active movement

- Weather protection – verify covers, flashings remain effective

Documentation:

- Photographs showing joint condition

- Measurements of joint widths and visible defects

- Notes on performance trends

- Recommendations for maintenance or repair

Maintenance and Repair

Proactive maintenance extends joint life and prevents failures.

Cleaning:

- Annual cleaning removes dirt and biological growth

- Gentle methods – avoid abrasives damaging sealant

- Verify no damage after cleaning

Minor repairs:

- Small cracks or tears – can sometimes be oversealed

- Local adhesion loss – remove affected section, clean, reseal

- Surface damage – may not require complete replacement

Complete replacement:

- Remove old sealant completely

- Clean and prepare substrates per original specifications

- Install new sealant following proper procedures

- Allow adequate cure before returning to service

Replacement timing:

- Plan proactive replacement at 15-20 years for premium products

- Earlier replacement in severe exposure (desert, coastal, industrial)

- Replace when: 30% of length shows deterioration, adhesion loss >20%, or hardening/brittleness evident

Những câu hỏi thường gặp

How wide should expansion joints be for buildings in hot climates?

Building expansion joints in hot desert climates like the Middle East require 50-100% wider spacing than temperate climates due to extreme temperature ranges. A 30-meter building section experiencing 60°C temperature swing creates approximately 22mm thermal movement in concrete – requiring minimum 40-50mm joint width with ±50% movement capability sealant, or 80-100mm with ±25% product. The extreme daily temperature cycling (40-50°C) in desert climates also accelerates sealant fatigue, favoring premium silicone products rated for extreme conditions. Calculate specific requirements using material thermal expansion coefficient, length between joints, and actual temperature range.

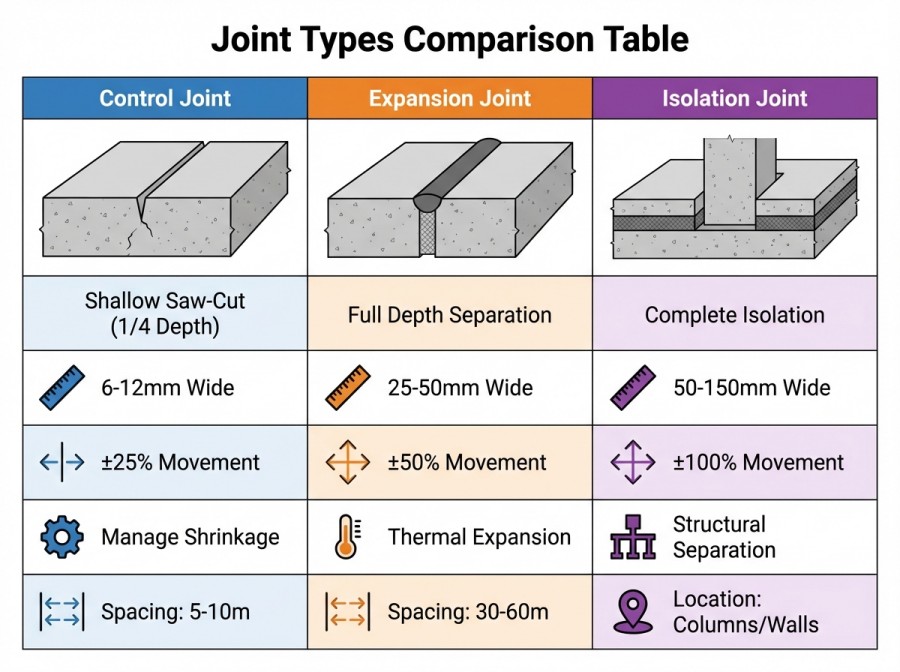

What’s the difference between control joints and expansion joints?

Control joints create intentional weak points in concrete inducing cracking at planned locations, while expansion joints provide complete structural separation allowing independent movement. Control joints typically use shallow sawcuts (1/4 to 1/3 depth) and remain 6-12mm wide, accommodating only concrete shrinkage and modest thermal movement. Expansion joints provide full-depth separation (25-50mm or wider) accommodating substantial thermal expansion, seismic displacement, and differential settlement between building sections. Expansion joints require high-movement sealants (±50% to ±100%) while control joints may use standard products (±25%). Think of control joints as “guided cracks” and expansion joints as “intentional separations.”

Can I use regular caulk in expansion joints?

No – regular acrylic or latex caulk lacks the movement capability, durability, and weather resistance required for expansion joints. Expansion joints demand sealants rated for ±25% to ±100% movement capability, while standard caulks typically handle only ±10% or less before failure. Quality expansion joint sealants – silicone, MS polymer, or polyurethane – maintain flexibility through decades of cycling, resist UV degradation, and adhere reliably to diverse substrates. Using inadequate products leads to premature failure typically within 1-3 years versus 15-25 years for proper materials. The cost difference between appropriate and inadequate products proves trivial compared to re-work expenses.

How often should expansion joint sealants be replaced?

High-quality silicone sealants in moderate conditions typically last 20-25 years before requiring replacement, while challenging exposures may reduce life to 10-15 years. Factors affecting longevity include: climate severity (desert/coastal accelerates aging), UV exposure intensity, daily temperature cycling magnitude, actual vs. designed movement, and sealant quality. Desert climates with 60-70°C temperature ranges and intense UV may require replacement every 10-15 years even with premium products. Plan proactive replacement when 20-30% of joint length shows deterioration rather than waiting for widespread failure. Annual inspection identifies approaching end-of-life conditions allowing planned maintenance versus emergency repairs.

What causes expansion joint sealants to fail prematurely?

The most common causes of premature expansion joint sealant failure are: undersized joints unable to accommodate actual movement (40% of failures), inadequate surface preparation preventing adhesion (30%), three-sided adhesion from missing backer rod (15%), and using inappropriate products for exposure conditions (15%). Undersized joints tear when movement exceeds capability – always include 25-50% safety factor beyond calculated movement. Poor surface prep leaves oils, dust, or old sealant preventing bonding – invest time in thorough cleaning and priming. Missing backer rod causes stress concentration and premature failure – never skip this critical step. Using economy products in severe exposure guarantees failure – match product capabilities to actual conditions.

Phần kết luận

Expansion joints represent critical building components preventing damage from thermal movement, seismic forces, settlement, and other dynamic loading – proper design, material selection, and installation ensure structures accommodate these movements gracefully throughout their service life. Without adequate expansion joints, buildings crack, cladding buckles, and envelope systems fail from forces that properly designed joints dissipate harmlessly.

Understanding movement sources and accurately calculating expected displacement forms the foundation of effective expansion joint design. Thermal expansion dominates most applications, with movement magnitude depending on material thermal expansion coefficient, length between joints, and temperature range. Desert climates with 60-70°C temperature ranges create movements 50-100% larger than temperate regions, demanding wider joints or higher-capability sealants.

Proper joint sizing balances movement accommodation with practical constraints. Joint width must provide adequate capacity for expected movement while maintaining sealant geometry for optimal performance – typically 2:1 width-to-depth ratio works best. Spacing guidelines vary by material and climate, with concrete structures typically requiring joints every 30-60 meters in temperate climates or 20-40 meters in extreme conditions.

Sealant selection should match movement capability to application demands. Standard ±25% movement products suit protected interior applications, while exterior envelope systems require ±50% capability minimum. Extreme applications – desert climates, seismic zones, or joints with combined movement sources – demand ±100% rated products. Silicone sealants deliver optimal performance for exposed applications through weather resistance, UV stability, and long-term flexibility.

System-specific requirements affect expansion joint design. Curtain walls combine thermal movement with inter-story drift requiring careful analysis. Floor slabs need joints managing both shrinkage and thermal effects while maintaining load transfer. Roofs face most extreme temperature ranges demanding robust systems with backup weatherproofing.

Installation quality determines real-world performance regardless of design excellence. Thorough surface preparation ensures adhesion, proper backer rod prevents three-sided adhesion failure, and correct application technique creates joints functioning as designed. Quality control through inspection and testing verifies specifications are met.

Regular inspection and proactive maintenance extend joint life while preventing small problems from becoming expensive failures. Annual inspection of critical joints identifies developing issues, while planned replacement after 15-25 years (depending on exposure) prevents catastrophic failures disrupting operations.

Whether designing new construction, specifying building systems, or maintaining existing facilities, expansion joint design and sealing demands systematic attention ensuring buildings handle dynamic forces effectively while protecting interior spaces and maintaining architectural integrity throughout decades of service.

Planning large-scale construction projects or need expert guidance on expansion joint design and material specifications? Contact our technical team for professional support on movement calculations, product selection, and installation specifications suited to your specific climate, structural system, and performance requirements.

Related Articles: